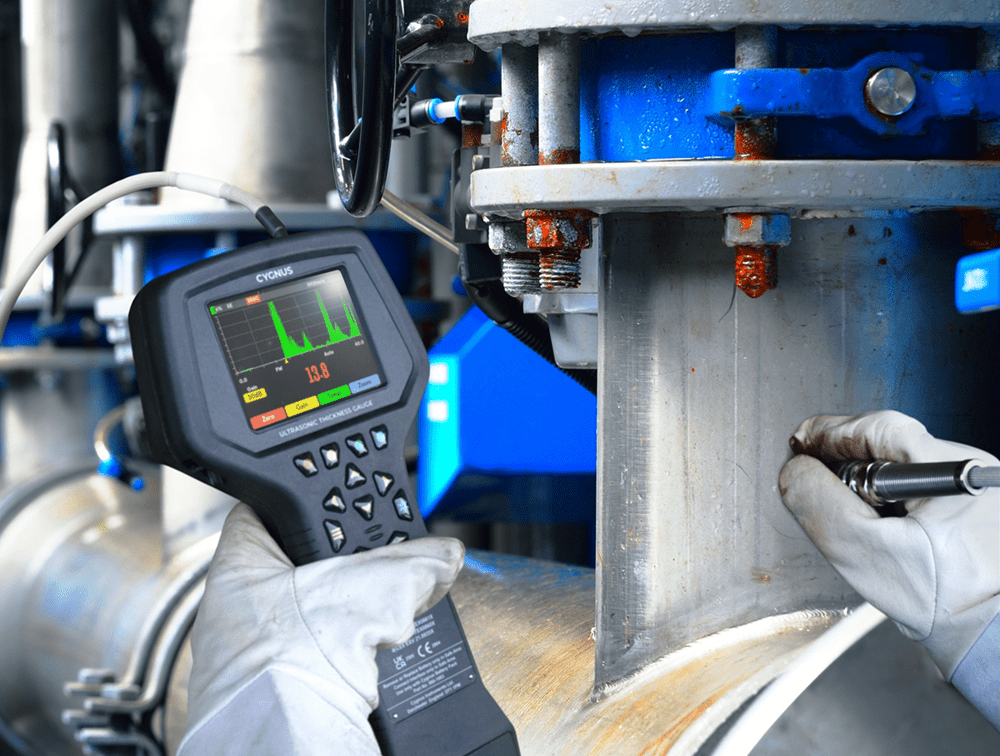

The maintenance and inspection of industrial piping systems are crucial to ensuring operational safety and efficiency. Corrosion, wear, and thinning of pipes can result in costly downtime or even catastrophic failures. This is why accurate pipe thickness measurement is essential. Among the most effective tools for this purpose are ultrasonic thickness gauges, which offer a non-destructive, precise, and reliable means of measuring metal thickness. Leading the way in this field is Cygnus Instruments, a company renowned for producing high-quality ultrasonic thickness gauges for diverse industrial applications.

The Importance of Measuring Pipe Thickness

In industries such as oil and gas, power generation, manufacturing, and chemical processing, pipes are subject to harsh environments that can cause degradation over time. Factors like internal corrosion, external rust, and erosion due to high-pressure flows can significantly weaken the pipe’s walls. Monitoring the remaining pipe thickness helps in detecting potential failures before they happen, preventing leaks, ruptures, and other safety hazards.

Accurate pipe thickness measurement is integral to maintaining the structural integrity of pipelines. With proper monitoring, businesses can proactively plan repairs, replacements, or maintenance activities, thereby extending the lifespan of their infrastructure and reducing the risk of unexpected shutdowns.

How Ultrasonic Thickness Gauges Work

Ultrasonic thickness gauges are widely considered the most effective and accurate method for measuring the thickness of pipes and other metal structures. These devices use high-frequency sound waves to measure the distance between the transducer and the opposite surface of the material being tested.

Here’s a breakdown of how the process works:

- Sound Wave Transmission: The gauge’s transducer emits an ultrasonic pulse, which travels through the material.

- Reflection of Waves: When the sound waves hit the far side of the material, they reflect back to the transducer.

- Time Calculation: The time taken for the sound waves to return is used to calculate the material’s thickness, with the speed of sound in the material being a known factor.

Ultrasonic thickness gauges are incredibly accurate and can detect changes in pipe thickness even in cases of minimal material loss. Moreover, these devices work effectively even if the pipe is covered in coatings or rust, making them ideal for inspecting pipes in real-world conditions.

Why Choose Cygnus Instruments for Pipe Thickness Measurement?

Cygnus Instruments has built a strong reputation for manufacturing top-tier ultrasonic thickness gauges that provide accurate and reliable results. With over 30 years of experience in the field, Cygnus offers a range of ultrasonic devices specifically designed for pipe thickness measurement, catering to various industries and applications.

Why Cygnus Instruments Stands Out:

- Industry-Leading Accuracy: Cygnus ultrasonic gauges are known for their precision. The company uses state-of-the-art technology to provide highly accurate readings, even for thin or corroded pipes. This helps businesses avoid the risk of failure and optimises maintenance schedules.

- Rugged Design for Tough Environments: Cygnus understands that pipes are often found in challenging environments such as offshore platforms, chemical plants, and power stations. Their gauges are built to withstand extreme temperatures, moisture, and vibrations, making them reliable tools for both field and workshop testing.

- User-Friendly Interface: Cygnus ultrasonic thickness gauges are designed for ease of use, even for non-experts. Clear displays, simple controls, and straightforward operation mean technicians can quickly take measurements, reducing the likelihood of human error.

- Data Storage and Reporting: Many Cygnus instruments offer data logging features, which allow users to store readings for future reference. These features are particularly useful for compliance documentation and long-term monitoring of pipe condition.

- Versatility Across Materials: While commonly used for measuring steel pipe thickness, Cygnus ultrasonic gauges are also versatile and can be used to measure the thickness of various metals, such as aluminium, copper, and cast iron, making them adaptable to multiple industrial needs.

Measuring Metal Thickness with Cygnus Instruments

The process of measuring metal thickness with an ultrasonic gauge is quick and non-invasive. Here’s a simple guide on how to use Cygnus ultrasonic thickness gauges to measure pipe thickness:

- Surface Preparation: Clean the surface of the pipe to remove any dirt, grease, or rust that could affect the measurement accuracy. This step ensures that the ultrasonic waves can pass through the material without interference.

- Calibration: Before using the gauge, calibrate it using a test block of known thickness. Calibration ensures that the readings you take are precise and consistent.

- Coupling the Transducer: Apply a thin layer of coupling gel to the surface of the pipe. This gel helps transmit the sound waves effectively, improving measurement accuracy.

- Taking Measurements: Place the transducer on the pipe’s surface, and activate the gauge. The device will display the thickness reading after calculating the time it takes for the sound wave to reflect back.

- Multiple Readings: For more accurate results, take multiple measurements at different points along the pipe. This will help identify areas where corrosion or erosion may have caused significant thinning.

- Recording and Analysis: Save the results for future analysis or reporting. Many Cygnus gauges feature data logging capabilities, allowing you to store readings and track changes in thickness over time.

Applications of Ultrasonic Thickness Gauges

Ultrasonic thickness gauges are employed across a variety of industries for measuring pipe thickness. Some of the most common applications include:

- Oil & Gas: Monitoring the integrity of pipelines that transport oil, gas, or chemicals to prevent leaks or failures.

- Power Generation: Ensuring that power plants’ steam and cooling pipes remain in good condition.

- Manufacturing: Inspecting pipes used in industrial systems to maintain production efficiency and safety.

- Marine and Offshore: Measuring the thickness of pipes on offshore platforms or ships to prevent costly corrosion-related incidents.

Conclusion

The use of ultrasonic thickness gauges is crucial for maintaining the safety and efficiency of industrial piping systems. Cygnus Instruments has set the standard for high-quality, durable, and accurate pipe thickness measuring instruments. Their ultrasonic gauges offer a reliable, non-destructive solution for industries looking to monitor and maintain the integrity of their piping systems. Whether you’re measuring metal thickness in the oil and gas sector, power plants, or manufacturing facilities, Cygnus Instruments provides the ultimate tools for ensuring the longevity and safety of your pipes. Investing in the right ultrasonic thickness gauge is an investment in the long-term health of your infrastructure, reducing downtime, preventing failures, and saving costs.