In today’s competitive marketplace, innovative product design is a critical factor for success. Businesses need manufacturing solutions that provide precision, efficiency, and flexibility to transform their ideas into reality. Custom plastic injection molding has become a cornerstone of modern manufacturing, empowering businesses to create complex and high-quality products tailored to their specific needs. At Petron Thermoplast, we specialize in offering advanced custom plastic injection molding services that elevate product design and bring visions to life.

What is Custom Plastic Injection Molding?

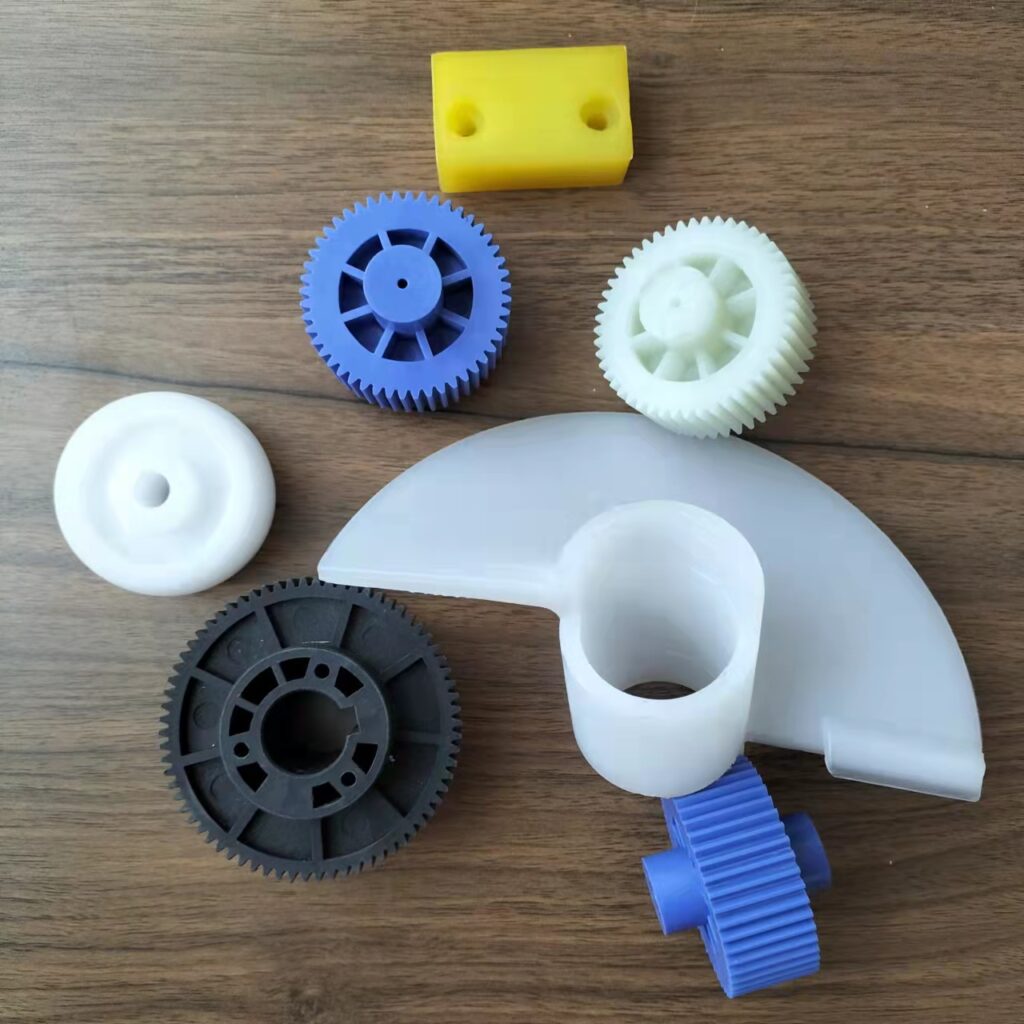

Custom plastic injection molding is a manufacturing process that involves injecting molten plastic into a precisely designed mold to produce a variety of components and products. Unlike standard injection molding, custom molding focuses on creating parts with unique specifications, tailored designs, and precise tolerances to meet specific industry or client requirements.

This process is widely used across industries such as automotive, medical, electronics, and consumer goods due to its ability to produce high-quality parts efficiently and cost-effectively.

The Role of Custom Injection Molding in Enhancing Product Design

Custom plastic injection molding plays a pivotal role in optimizing product design and functionality. Here’s how:

-

Design Flexibility

Custom molding allows for the creation of intricate and complex designs that would be challenging or impossible to achieve with other manufacturing methods. Designers can incorporate:

- Detailed geometries

- Complex surface textures

- Multi-functional components

This flexibility enables innovative product designs that stand out in the market.

-

Precision and Accuracy

At Petron Thermoplast, we utilize advanced molding technologies to achieve exceptional precision and consistency. Custom molds are designed to tight tolerances, ensuring that every part produced meets exact specifications. This is particularly important for industries like medical and aerospace, where accuracy is critical.

-

Material Versatility

Custom plastic injection molding supports a wide range of materials, including high-performance plastics such as PEEK, polycarbonate, and UHMWPE. This versatility allows product designers to choose materials that offer the ideal balance of strength, flexibility, thermal resistance, and chemical resistance for their applications.

-

Prototyping and Iterative Design

Custom injection molding facilitates rapid prototyping, enabling designers to test and refine their ideas before full-scale production. This iterative approach helps:

- Identify potential design flaws

- Optimize functionality

- Reduce time-to-market

-

Cost Efficiency

While the initial investment in custom molds may seem high, the efficiency of the injection molding process results in lower production costs for high-volume manufacturing. Additionally, custom molds minimize material waste, further reducing overall costs.

-

Enhanced Aesthetics

Custom molds enable the incorporation of aesthetic features, such as:

- Vibrant colors and finishes

- Branding elements like logos or patterns

- Seamless and polished surfaces

These enhancements improve product appeal and create a strong impression on customers.

-

Integration of Advanced Features

With custom injection molding, designers can integrate advanced features like:

- Snap-fit joints

- Overmolding for multi-material parts

- Reinforced areas for added strength

This integration enhances the functionality and usability of products.

Applications of Custom Plastic Injection Molding

Custom injection molding benefits a wide range of industries, including:

-

Automotive

Precision-engineered parts like dashboards, door panels, and engine components.

-

Medical

Biocompatible and sterile components such as syringes, implants, and diagnostic tools.

-

Consumer Electronics

Housings, connectors, and other intricate parts for electronic devices.

-

Aerospace

Lightweight and durable components that meet stringent safety standards.

-

Packaging

Custom packaging solutions with unique shapes, closures, and branding elements.

Why Choose Petron Thermoplast for Custom Plastic Injection Molding?

At Petron Thermoplast, we combine expertise, state-of-the-art technology, and a customer-centric approach to deliver exceptional custom injection molding services. Here’s why we are the preferred choice:

-

Expert Design Support

Our experienced team collaborates closely with clients to understand their needs and translate them into efficient, manufacturable designs.

-

Cutting-Edge Technology

We utilize advanced molding machines and techniques to produce parts with unmatched precision and quality.

-

Material Expertise

We offer a broad selection of high-performance materials to meet the specific requirements of each project.

-

End-to-End Solutions

From initial design and prototyping to full-scale production, we provide comprehensive support at every stage of the manufacturing process.

-

Commitment to Quality

At Petron Thermoplast, quality is non-negotiable. Our rigorous quality control processes ensure that every product meets or exceeds industry standards.

Conclusion

Custom plastic injection molding is a powerful tool for enhancing product design, offering unparalleled flexibility, precision, and efficiency. At Petron Thermoplast, we take pride in helping businesses transform their innovative ideas into reality with our top-notch custom injection molding services. Whether you’re developing a new product or improving an existing design, our team is here to deliver solutions that meet your exact needs.