In the modern world of manufacturing, precision and automation play pivotal roles in achieving quality production, reducing errors, and improving efficiency. One of the most essential tools in industries that deal with cylindrical components is the PLC external cylindrical grinding machine. This machine offers high accuracy, consistency, and productivity, making it indispensable for many sectors like automotive, aerospace, and engineering.

In this article, we’ll explore the uses of a PLC external cylindrical grinding machine, how it functions, and why it’s essential in precision grinding operations.

What Is a PLC External Cylindrical Grinding Machine?

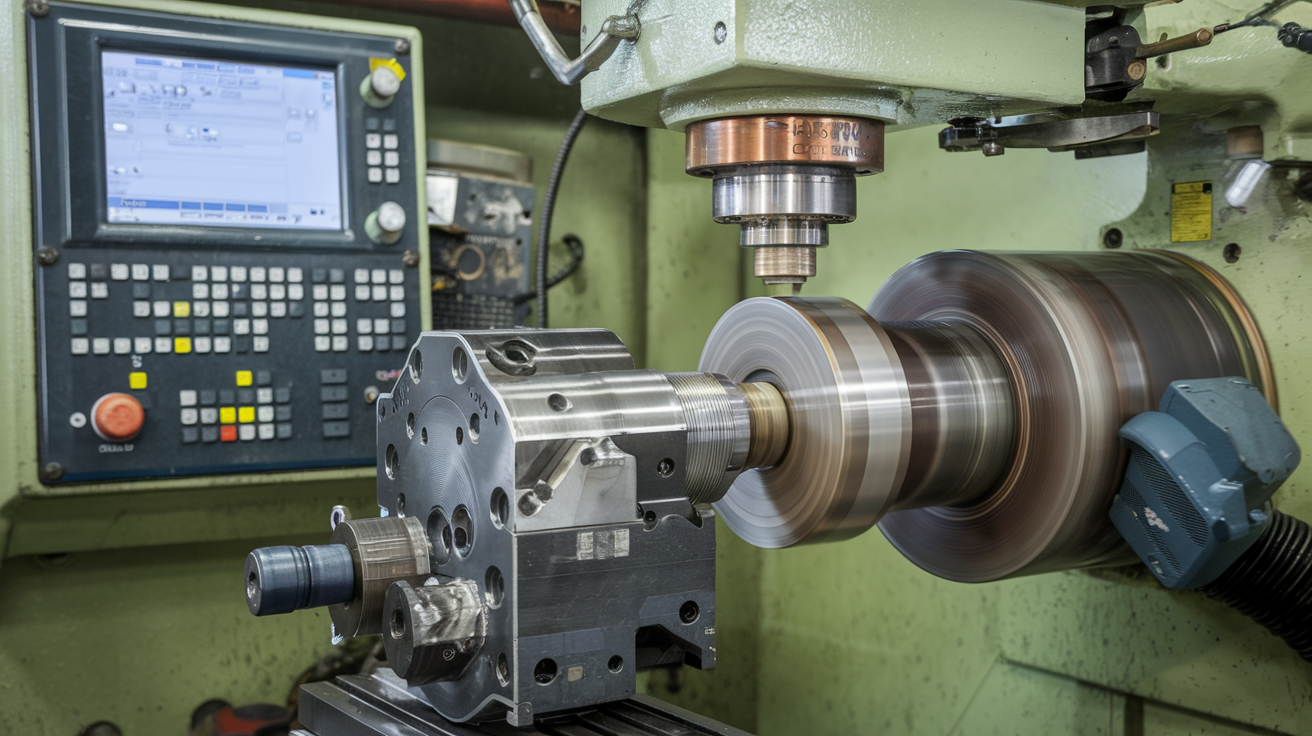

A PLC external cylindrical grinding machine is a type of grinding machine that uses a Programmable Logic Controller (PLC) to automate the grinding process. The machine is specifically designed for grinding the external surfaces of cylindrical components, such as shafts, rods, or tubes.

Grinding is a finishing process that removes a small amount of material to improve the surface finish and achieve tight dimensional tolerances. External cylindrical grinding refers to the machining of the outer surfaces of a workpiece. A PLC system provides automation and control, allowing for precise movements and consistent results.

The PLC system ensures that the entire grinding process is automated, with programmed instructions guiding the grinding wheel’s movement, speed, and pressure. This automation minimizes human error, reduces the need for manual intervention, and enhances the machine’s overall efficiency.

What Is a PLC External Cylindrical Grinding Machine Used For?

The PLC external cylindrical grinding machine is used for various applications in industries that require high precision and fine surface finishes. Here are some of the common uses of this machine:

Precision Grinding of Cylindrical Components

The primary use of a PLC external cylindrical grinding machine is to grind the external surfaces of cylindrical parts. These parts are often found in mechanical components, such as shafts, rollers, bearings, and axles. Precision grinding is essential to ensure that these components fit accurately in their assemblies and perform their functions without issues.

Grinding allows manufacturers to achieve tight tolerances, often in the range of micrometers, which would be difficult to achieve with other machining processes. This precision is vital for industries where high performance and reliability are critical.

Finishing Operations

After parts have been machined, they often require finishing to meet specific surface quality requirements. A PLC external cylindrical grinding machine is used to perform finishing operations by removing small amounts of material from the surface to create a smooth finish. This process is particularly important in industries like automotive and aerospace, where smooth surfaces reduce friction and wear, extending the lifespan of components.

Grinding Hard Materials

Cylindrical grinding machines are particularly useful for grinding materials that are difficult to machine with other methods, such as hardened steel, ceramics, and certain alloys. The grinding wheel, often made from abrasive materials like aluminum oxide or silicon carbide, can remove material from these hard surfaces with high precision. This capability makes the PLC external cylindrical grinding machine an essential tool in industries that work with tough materials.

Manufacturing of Round Parts

Industries such as automotive, aerospace, and mechanical engineering often require perfectly round parts for their applications. The PLC external cylindrical grinding machine is essential in the manufacturing of these round parts, such as precision shafts, rods, pins, and rollers, ensuring that they meet the required specifications for both form and size.

Batch Production of Cylindrical Components

For manufacturers involved in large-scale production, especially in industries like automotive, batch production of cylindrical parts is common. A PLC external cylindrical grinding machine is ideal for this type of production because it can be programmed to perform repetitive grinding tasks with consistent quality. This automation reduces setup times and increases productivity, allowing companies to meet high production demands.

Grinding Tapers and Angles

In some cases, external cylindrical grinding may involve grinding tapered surfaces or angles on cylindrical components. This is a critical function in applications where specific taper angles are required for proper fit and function. The PLC system enables precise control over the grinding process, ensuring that these angles are accurately machined.

Key Features of a PLC External Cylindrical Grinding Machine

The PLC external cylindrical grinding machine comes equipped with several features that make it suitable for a wide range of applications. Some of the key features include:

1. Automated Control

The Programmable Logic Controller (PLC) enables automation of the grinding process. The machine’s parameters, such as feed rate, wheel speed, and grinding depth, can be programmed in advance. This automation ensures consistent quality and repeatability, which is essential for mass production.

2. High Precision

PLC-controlled cylindrical grinding machines offer exceptional precision, making them ideal for tasks that require tight tolerances. The machine’s ability to maintain accuracy over extended production runs ensures that all parts produced meet the required specifications.

3. Versatility

The PLC external cylindrical grinding machine can be used to grind various types of materials and shapes. Whether the workpiece is a cylindrical shaft, a conical part, or a tapered component, the machine can adapt to different geometries.

4. Efficiency and Speed

With automation provided by the PLC system, grinding cycles are completed more quickly compared to manual grinding. The ability to program multiple grinding steps allows for faster processing times and increased throughput.

5. Enhanced Safety

The automation provided by the PLC system reduces the need for direct operator involvement, enhancing safety in the workplace. Operators can monitor the process remotely, and the machine is equipped with safety features to prevent accidents.

6. User-Friendly Interface

Modern PLC external cylindrical grinding machines come with user-friendly interfaces that allow operators to easily program and control the machine. These interfaces often include touchscreen displays and simplified navigation, making it easier for operators to set up and monitor grinding operations.

Why is a PLC External Cylindrical Grinding Machine Important?

1. Improves Productivity

One of the primary reasons industries invest in PLC external cylindrical grinding machines is to improve productivity. The automation and precision offered by the PLC system allow manufacturers to produce large volumes of parts with minimal downtime.

2. Reduces Errors

Manual grinding processes are prone to errors caused by operator fatigue, miscalculations, or inconsistency in technique. A PLC system eliminates these issues by automating the entire process and ensuring that each part is ground to the exact specifications.

3. Cost-Effective for Long Production Runs

For manufacturers involved in long production runs, a PLC external cylindrical grinding machine proves to be cost-effective. Its ability to consistently produce high-quality parts reduces the need for rework or scrap, lowering overall production costs.

4. Meets Industry Demands for Precision

Industries like aerospace and automotive demand high levels of precision and quality in their components. A PLC external cylindrical grinding machine is capable of meeting these stringent requirements, making it a vital tool in these sectors.

5. Increases Flexibility

The versatility of a PLC external cylindrical grinding machine allows it to handle various materials and geometries, providing flexibility in manufacturing operations. This flexibility means that manufacturers can use the machine for different types of parts without needing multiple specialized machines.

Conclusion

A PLC external cylindrical grinding machine is a critical piece of equipment for industries that require high precision and quality in cylindrical components. Its automation, precision, and versatility make it ideal for grinding tasks in sectors such as automotive, aerospace, and engineering. Whether for batch production or custom part finishing, this machine plays a vital role in ensuring that cylindrical parts meet the necessary specifications, while also improving productivity and reducing errors. With the integration of PLC technology, these machines continue to push the boundaries of what is possible in precision grinding.