Introduction:

In this post, we will share information about reverse engineering services and how 3D scanning services are used for design. An important step in the manufacture of almost anything, and one that determines nearly the entire design and manufacturing process, is to determine the three-dimensional shape of your mold.

In the past, the first bodies were made from wood, clay, or other readily available materials to keep the concept alive in the early stages of development. Although this practice still exists, as we see in the automotive design industry, now more advanced methods are used: CAD services and 3D scanning.

3D scanning is an important tool to support manufacturing. By creating digital 3D models of real objects, manufacturers can design, prototype, and manufacture them with greater accuracy and efficiency.

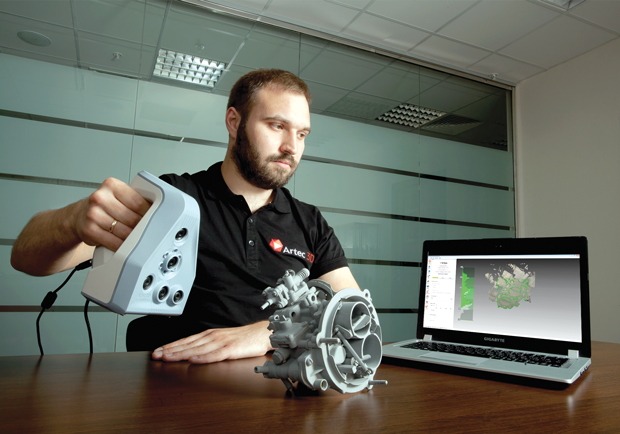

3d Scanning Reverse Engineering

Engineers and designers are increasingly using 3D scanning to facilitate decision-making in the manufacturing process or in factory design and process planning. During the design process, reverse engineering 3D scanning involves obtaining information about existing physical objects and engineering them in a realistic environment.

At the longitudinal level, this behavior is subtle. There are several methods of measuring objects in 3D scanning services. These include laser scanners, light scanners, coordinate measurement (CMM), and industrial CT scanners.

Raw measurement data are usually collected as point cloud data that must be converted to a more usable format, such as mesh or CAD models. This is usually accomplished using a tracking system with switching software.

What Are the Benefits of Using 3d Scanning for Reverse Engineering?

3D Scanning reverse engineering services are the easiest way to determine the geometry of any object, and the information they provide can be manipulated and modified to repair or repair broken original parts.

The main advantages of using a 3D scanner for reverse engineering are:

- Complexity: 3D scanners can process even complex parts by measuring millions of points on each surface.

- Speed: 3D scanners collect data faster than contact technologies.

- Completion: 3D scanning services provide a complete image of the part, enabling the elimination of cracks or deviations from the part’s original shape.

- Convenience: The 3D scanner is easy to transport anywhere.

How 3d Scanning and Reverse Engineering Services Transform Product Development

3D scanning and reverse engineering process are transforming manufacturing with many benefits, including:

- Accurate Digital Models: Create accurate digital copies of physical objects that allow for accurate analysis and manipulation.

- Time and cost savings: Use existing methods to reduce prototyping costs and speed up the development cycle.

- Innovative design: 3D scanning reverse engineering services combine existing materials with new ideas to create unique solutions.

- Quality Control: Ensure components meet specifications and tolerances.

- Reproduction of legacy parts: Reproduction of obsolete or obsolete parts without original CAD data.

- Product development: industrial 3D scanning helps to analyze and improve the design of existing products.

- Collaboration and communication: Facilitate collaboration by sharing detailed digital models with stakeholders.

Benefits of Reverse Engineering

It’s a great time for the electronics assiduity. The company is growing at an unknown rate. Still, this growth puts pressure on companies to pay close attention to operations, design, and manufacturing. This is why switching technology has become commonplace. Easy to find and use.

Reverse engineering is the process of probing a product or element to determine how and why it works. The reverse engineering process allows engineers to destroy the product. It can be customized for various purposes, including all project documentation.

In an industry where it is important to stay ahead of the competition, project innovation can bring significant benefits to the product and the manufacturer.

- Check out the current maps and how they are done.

In reverse engineering, we look at what already exists. It includes any process, process, or system that might otherwise benefit society. Exploring existing products leads to innovation and discovery, all thanks to revolutionary technology.

- Restore expired products.

A key to transforming an existing product is understanding the product itself. Reverse engineering provides information on how to solve old problems in an outdated system. The most important benefit of reverse engineering is quality.

- Bring cheaper and more efficient products to the market.

The primary purpose of 3D scanning reverse engineering services is to guide engineers on the path to innovation and success. Being successful means minimizing production costs and maximizing product efficiency.

- Inspire creative minds with original ideas.

Eventually, innovative techniques are replaced by adaptive technology. In doing so, the engineer may discover a configuration that may be useful for another application. Demonstrate how to relate technical skills to prior knowledge.

Conclusion

Fibrox 3D uses proprietary hardware and software to capture the shape and structure of physical objects and transform them into digital 3D models. The resulting industrial 3D scanning can be used for numerous operations, such as visualization, modeling, and fabrication. Rear engineering is the process of rooting design information from a system or object and also using that information to rebuild or modify the product or system.

Read More: The Role of Large Scanner Services in Modern Analysis